The specialists for environmental technology

FSM - Screenings Cutter

FSM - Screenings Cutter

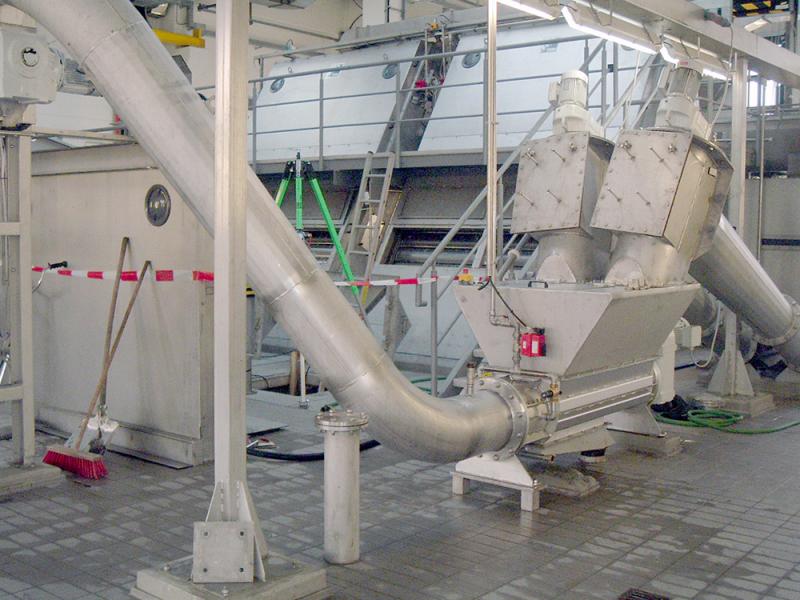

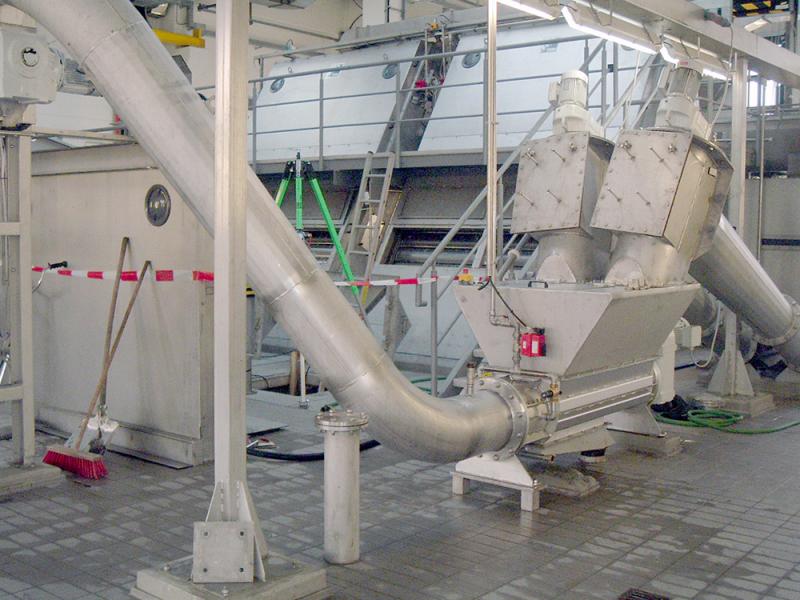

The FSM screenings cutter provides hygienic and efficient treatment of screenings

Disposal of screenings is a cost factor in every installation. Wet screenings are heavy screenings and inflate costs. The FSM screenings cutter reduces the weight and volume of your accumulated screenings. Furthermore, 95% of fecal matter is washed out.

The screenings wash compactor produces large pellets which are ejected into a container at the end of the discharge pipe. These pellets lead to a loss of storage capacity and restrict distribution within the container.

By installing a screenings cutter at the discharge pipe, large pellets are broken up into smaller pieces. This prevents the emergence of dead spaces and the container volume can thus be better exploited.

The increase in surface area leads to better final drying and the screenings can be more easily spread out if necessary.

Screening cutters combine high performance with low operating costs.

Functional principle:

The device can be directly flange-mounted on a discharge pipe.

The compactor presses the pellets against the spiral screw of the screenings cutter, thus rasping the cluster, so that only small lumps drop into the container.

Optional features:

A back pressure device, a swivelling device or a Bagging unit can be installed at the end of the discharge pipe.

Applications - Screenings Cutter

Applications in municipal and industrial clarification plant

• waste water pre-treatment / fine screening

• sludge screening / secondary sludge

• sludge screening / primary sludge

• sea water discharge

• rainwater tank overflow and storage channel screening

• septage reception and Treatment

Applications in the paper and cellulose industry

• coarse matter runoff, channel water

Applications in power plants

• Cooling- and fabrication water intake

• Seawater intake

Applications in the Industrie

• meat, fish and poultry processing / slaughterhouses – preliminary clarification of total waste water

• Sugar industrie – preliminary clarification of total waste water

• composting installations, waste product and disposal engineering, seepage water treatment

• fruit and vegetables – preliminary clarification of total waste water

• brewery - preliminary clarification of total waste water

• disposal of wet debris and kitchen waste

• disposal of foodstuffs and food waste

Features, Dimensions and Material

Features:

• High reliability through robust construction

• Reduction of waste disposal costs, minimising of volume and weight of screenings

• Made of stainless steel, except wear parts

• Easily retrofitted to an existing installation, because flexible and adaptable

• Excellent cost/performance ratio

• Low maintenance costs

• Suitable for outdoor sites / operation in winter

• Machine completely hygienically encapsulated

Dimensions:

types AF 450

diameter 400 mm

troughput up to 10 m³/h

Material/make:

machine housing stainless steel SS304 or SS316, other materials on request

conveyor screw extremely wear resisting steel

wear strips HDPE

drives geared motors, make SEW

Videos

There is currently no video available for this product.

Weltweit zufriedene Kunden.

Wir sind seit vielen Jahrzehnten die Spezialisten der Wasser- und Abwasserreinigung und haben unzählige Projekte im In- und Ausland erfolgreich ausgeführt.

Gerne senden wir Ihnen unsere umfangreiche und aussagekräftige Referenzliste zu.

Hierzu benötigen wir Ihren Namen, Ihre Anschrift und Ihre Telefonnummer.

Bei der telefonischen Rücksprache klären wir in einem kurzen Gespräch Ihr spezielles Bedarfsprofil, um Ihnen dann umgehend und zielgerichtet die gewünschten Informationen zuzusenden.

Bitte senden Sie uns eine kurze E-mail, verwenden Sie den "Anfrage" Button oder rufen Sie uns doch einfach an.

Wir freuen uns über Ihr Interesse.

Your contact

Consulting & Support

Address

FSM Frankenberger GmbHOperating facility Pohlheim

Vor dem Hohen Stein 1D-35415 Pohlheim

Tried and trusted products

Productive throughout the range: technological mastery and the very best service.

Customer-orientated

Understanding enquiries and problems in order to develop specifically targeted solutions.

Used throughout the world

Exciting projects successfully implemented in over 20 countries on 5 continents.

Trimmed for throughput

High throughput, reliability and service quality. Fully developed concepts for the high demands of daily realities.

Sustainable concept

Thinking about tomorrow today. We have been developing products designed to be sustainable, flexible and durable with this in mind for 50 years.

Innovative design

Integrated solutions at the highest technological level, seamlessly adapted to the existing workflow by our engineers.

Important Links

Stammsitz

FSM Frankenberger GmbH

Friedrichstr. 95

D-10117 Berlin